Equipment

Backed by more than 30 years of manufacturing expertise from MFE Enterprises, MFE Middle East provides access to proven MFL tank floor scanners built to perform in demanding industrial inspection environments worldwide.

Featured Equipment

MFE Mark IV Tank Floor Scanner

The MFE Mark IV is designed for efficient, full-coverage inspection of aboveground storage tank floors.

Using proven magnetic flux leakage technology, it supports reliable detection of corrosion, pitting, and metal loss across large floor areas—delivering accurate, real-time data to support confident integrity assessments.

The system is capable of scanning through up to 12.7 mm (½ inch) of combined steel and coating, with an optional High Flux Bridge extending capability to approximately 19 mm (0.75 inch) for thicker floor configurations.

Available through MFE Middle East for rental, sale, or proof of concept, the Mark IV is built to perform in demanding inspection environments worldwide.

Equipment Type: MFL Tank Floor Scanner

Built for Efficient Tank Floor Inspections

Designed on decades of MFL manufacturing experience

Lightweight, balanced design for easier handling in the field

Continuous scanning without unnecessary interruptions

Built to support long inspection days and tight shutdown schedules

Why it matters: Less fatigue, fewer stoppages, and smoother inspections from start to finish.

Intuitive Software That Simplifies Mapping

User-friendly mapping software reduces setup and learning time

Quickly build a digital tank floor layout before scanning begins

Switch easily between manual scanning and guided mapping modes

Generate clear, comprehensive MFL maps through a guided workflow

Why it matters: Faster setup, fewer errors, and clear inspection data without complex processes.

Consistent Results You Can Trust

Real-time feedback helps operators maintain consistent scan quality

Live visualisation supports faster defect identification

Built-in safeguards help normalise results across varying scan speeds

Improved handle locking enhances stability and control during operation

Why it matters: More reliable data, greater confidence in results, and reduced rework during inspections.

Download your brochure

Download the brochure to learn more about the MFE Mark IV MFL tank floor scanner, including key features, applications, and deployment options available through MFE Middle East.

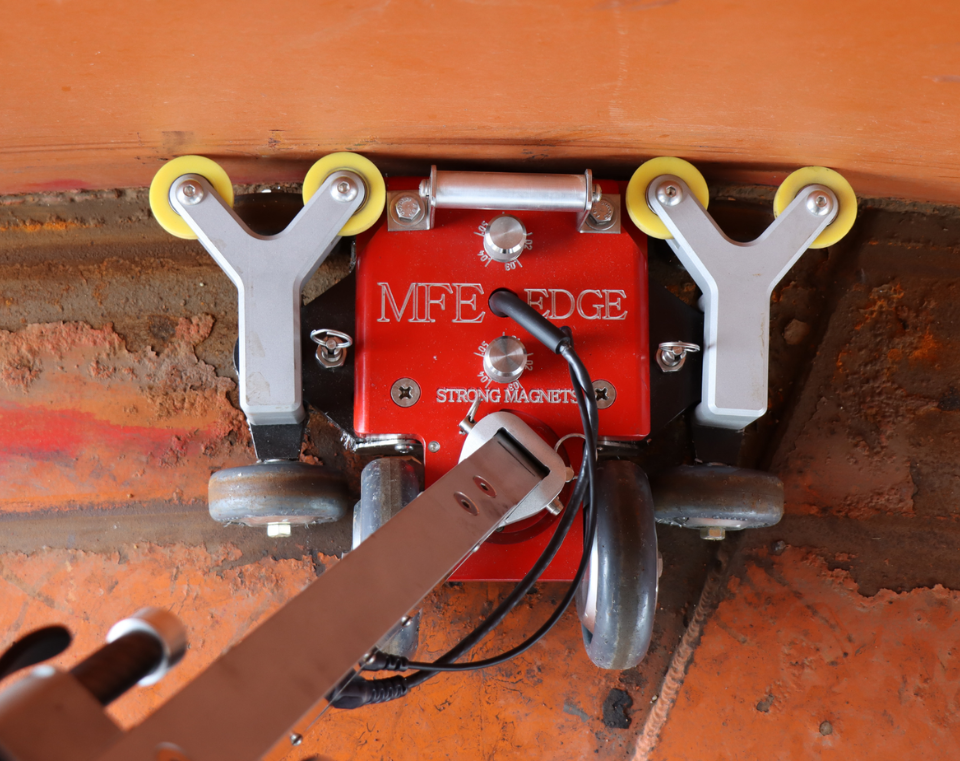

MFE Edge Tank Floor Scanner

The MFE Edge is purpose-built for inspecting the most critical and difficult areas of aboveground storage tanks—the floor-to-shell interface. Using proven MFL technology, it helps inspection teams identify early-stage corrosion where deterioration most often begins.

Designed for edge-zone access, the MFE Edge operates extremely close to the tank shell, allowing reliable evaluation of tight, hard-to-reach areas that standard floor scanners cannot fully cover. Its straightforward operation supports efficient inspections without adding complexity in the field.

When used alongside the MFE Mark IV, the MFE Edge provides a complete inspection approach—combining wide-area floor coverage with focused edge inspection. Available through MFE Middle East for rental, sale, or proof of concept, the MFE Edge supports confident tank integrity assessments across global inspection programmes.

Equipment Type: MFL Tank Floor Edge Scanner

Precision Where Corrosion Begins

Purpose-built for the tank floor–to–shell interface

Identifies corrosion and metal loss in the most critical edge zone

Delivers clear, actionable edge-condition data for maintenance planning

Strengthens overall tank integrity and inspection programmes

Why it matters: Early edge-zone insight helps prevent small issues from becoming costly repairs.

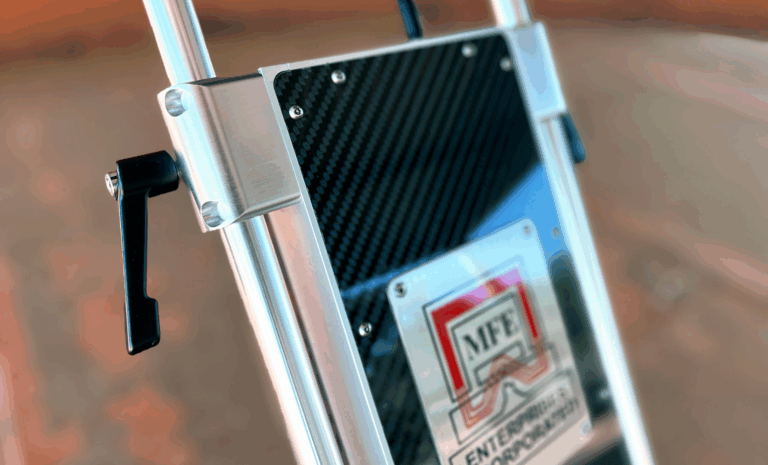

Designed for Tight, Real-World Conditions

Pivoting handle allows close access along the tank shell

Compact, balanced design supports controlled scanning in confined areas

Easy to manoeuvre without adding complexity for operators

Built for efficient deployment during shutdowns and tight schedules

Why it matters: Inspect areas other scanners struggle to reach—without slowing the inspection down.

Seamless Integration with Mark IV Workflows

Shares a familiar, user-friendly software experience

Supports both manual inspection and guided mapping workflows

Edge inspection results integrate smoothly with Mark IV floor data

Enables a complete inspection approach without duplicate effort

Why it matters: One connected workflow for wide-area floor coverage and detailed edge inspection.

Download your brochure

Download the brochure to learn more about the MFE Edge MFL tank floor scanner, including key features, applications, and deployment options available through MFE Middle East.

Recent Upgrades

Driven by field feedback and ongoing development, recent updates to the MFE Mark IV focus on improved durability, greater operational reliability, and reduced maintenance requirements—enhancing performance and ease of use in demanding inspection environments.

Durable aluminium handles for demanding field conditions

Reinforced aluminium handles provide long-term durability and a stable grip, built to withstand daily use in harsh inspection environments.

Lightweight, field-ready design

A lighter, foldable handle design improves manoeuvrability and transport while maintaining the structural strength required for repeated field deployment.

Secure dual cam levers for dependable locking

Upgraded dual cam levers deliver a firm, reliable lock, helping maintain scanner stability and operator confidence throughout each inspection pass.

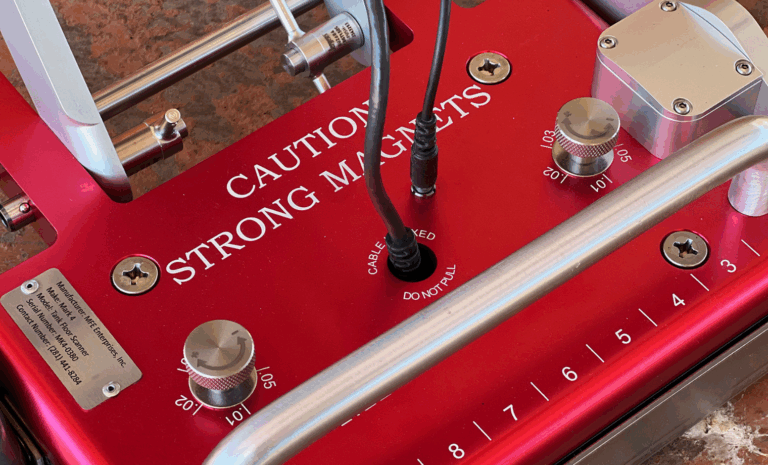

Fixed signal cable for improved reliability

A permanently attached signal cable reduces common connection failures, helping minimise downtime and keep inspections progressing without interruption.

MFL Equipment You Can Trust

Tank Floor Integrity Assessments: Perform efficient, full-coverage inspections of aboveground storage tank floors to identify corrosion, pitting, and metal loss.

Planned Shutdown & Turnaround Inspections: Deploy MFL scanners during scheduled outages to assess tank floor condition quickly and support informed maintenance decisions.

Baseline & Ongoing Condition Monitoring: Establish baseline data on new or refurbished tanks and track changes over time to support asset integrity programmes.

Pre-Repair & Post-Repair Verification: Validate defect locations before repairs and confirm effectiveness after maintenance or floor replacement.

Regulatory & Compliance Inspections: Support inspection programmes aligned with industry standards by generating reliable data for reporting and audit requirements.

Challenging or Large-Scale Assets: Inspect large-diameter tanks and hard-to-access floor areas where manual or spot inspections are inefficient or impractical.

Aboveground Storage Tanks (ASTs): Inspect tank floors for corrosion, pitting, and metal loss across crude oil, refined products, and chemical storage.

Large-Diameter Storage Tanks: Efficiently scan expansive tank floors where manual or spot inspections are time-consuming and limited.

Floating Roof & Fixed Roof Tanks: Support inspections across different tank configurations during shutdowns and maintenance windows.

Terminal & Tank Farm Assets: Assess tank floor condition across multi-tank facilities to support asset integrity and maintenance planning.

Aged or High-Risk Tanks: Identify areas of concern in older tanks or assets with known corrosion risk or historical issues.

New or Recommissioned Tanks: Establish baseline inspection data following construction, repairs, or return to service.

Oil & Gas (Upstream, Midstream & Downstream): Tank floor inspections supporting asset integrity, corrosion management, and regulatory compliance across production, storage, and refining facilities.

Tank Terminals & Storage Facilities: Routine and turnaround inspections for crude, refined products, and bulk storage tanks across multi-tank sites.

Petrochemical & Chemical Processing: Inspection support for tanks storing chemicals and feedstocks where corrosion risk and containment integrity are critical.

Power Generation & Utilities: Tank inspections for fuel oil, water, and auxiliary storage assets supporting continuous plant operations.

Aviation Fuel Storage: MFL scanning for tank floors used in jet fuel storage, helping maintain safety and compliance standards.

Mining & Industrial Processing: Assessment of storage tanks used for process liquids, fuels, and industrial materials.

EPCs & Inspection Service Providers: Equipment access for inspection contractors supporting asset owners during shutdowns, repairs, and maintenance programmes.

Buy or Rent

Request a Quote